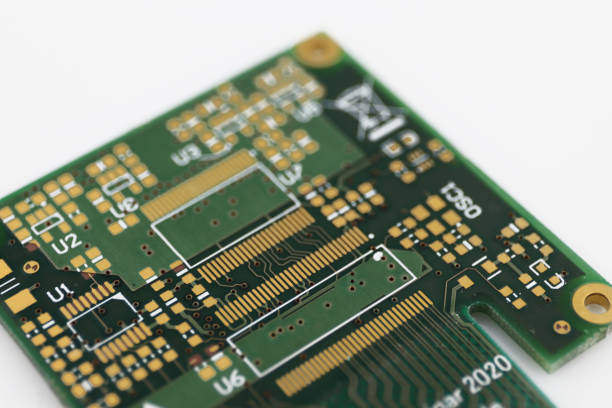

You’re probably aware of the importance and necessity of printed circuit boards, generally known as PCBs. The design of printed circuit boards is mostly dictated by a list of specifications provided by the client to the manufacturer.

The requirements are determined by a variety of elements, the majority of which are dependent on the end product’s capabilities and characteristics. A PCB prototype is created to satisfy these specifications, allowing for scale manufacture as needed by the client.

PCB Prototypes Obtaining PCB Prototypes

The worried client contacts one of the experienced manufacturers in the sector with their set of specifications before production of printed circuit boards or PCB manufacturing can begin. The prototype is the most important concern at this point. Some manufacturers are superior than others for obvious reasons, and they can complete the prototype in less time.

Some Printed Circuit Boards demand extra time, particularly if the requirements are complex. At the same time, some prototypes can be designed with as few as two layers, while others may require 30 or more. It’s also critical to concentrate on the prototype’s size and functioning, as it must meet the design and box requirements. Every layer and copper trace is critical, and they must be constructed with extraordinary precision. Furthermore, testing is carried out at multiple levels to ensure that all criteria and functionalities have been accomplished.

Points to Consider

The PCB prototype is an important phase that decides how PCBs are used in the end, thus the design and manufacturing process should be as precise as possible.

The concerned manufacturer must have a staff that can maintain the PCB prototype’s integrity while keeping track of the client’s requirements. Printed Circuit Boards are generally tested several times, and it requires more than a few independent tests to ensure that all capabilities function as planned. The concerned manufacturer will keep track of the findings and resolve any potential issues in a recorded manner.

Locating a Producer

When it comes to PCB prototyping, most clients aren’t interested in learning about the manufacturing process; all they want is a working PCB prototype that can be mass produced. If that’s the case, look for well-known organizations with a strong reputation in the marketplace.

They should be able to assist you with your needs and have a good reputation for PCB prototyping and PCB manufacturing. They should also have the necessary capital and infrastructure in place to support complete production, as well as a team that is accessible, available, and willing to try new things.

Of course, you’ll need a deadline for the PCB prototype in question, and the manufacturer should also provide a full assessment of their manufacturing process along with an estimate.

Because the costs are supposed to be scalable, request a full quote. Inquire about their references to gain a better understanding of their work.

ChinaPCBOne Technology LTD. is the author of this article on PCB prototype. Find more information, about PCB manufacturing.